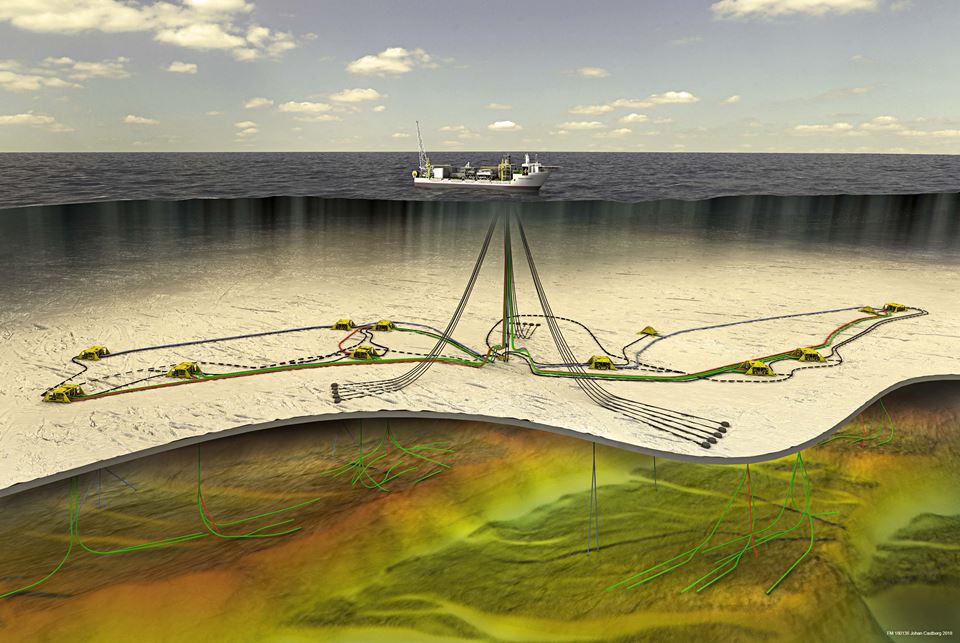

About 250 km from Hammerfest, the world’s northernmost town in Norway, in the inhospitable Barents Sea, lies the pristine oil and gas field Johan Castberg. At present a special production and storage vessel full of Norwegian-developed technology is being built to help extract oil and gas from this field.

The vessel, which will be anchored in one of the world’s toughest ocean climates, requires technical solutions of the highest quality. This is why Aker Solutions and Equinor have chosen a unique solution developed by Protan and Norwegian fire protection company, Firesafe Energy AS, to protect the assets and installations on the vessel’s deck from the Arctic ocean’s extreme climate.

Equipped in Norway

The ship is classed as an FPSO, an abbreviation for Floating Production, Storage and Offloading platform. At the Kværner shipyard in Stord, Norway, the vessel’s deck is being equipped with a range of large process modules and technical installations. These include extensive living quarters for up to 120 cabins. It is these living quarters that will be protected with the solution developed by Protan/Firesafe.

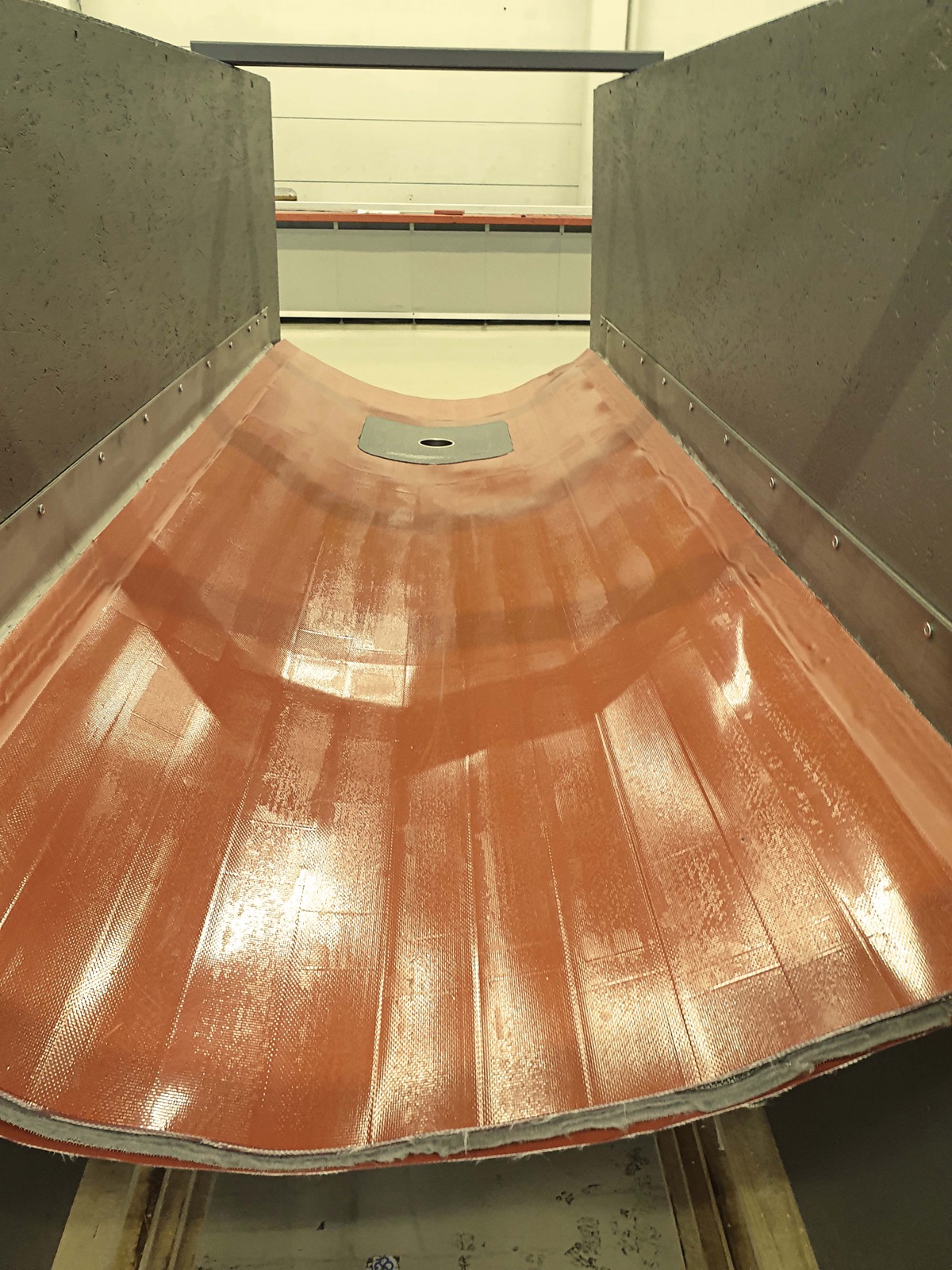

“In short, this is about 700 metres of flexible fire barriers that will be mounted between the various modules and barrier walls on the complex deck of the production vessel,” explains Firesafe CEO Erik Ulevik.

These fire barriers are manufactured in extremely fire-retardant materials developed to prevent blowouts and fires in the petroleum industry. They will be welded between the enormous modules and deck sections of the almost 300-metre-long vessel. The purpose of the barrier walls is both to ensure safe evacuation, by stopping the spread of fire, to lead surface water away and protect people and installations underneath from wind, rain and falling ice.

Requires material of the highest quality

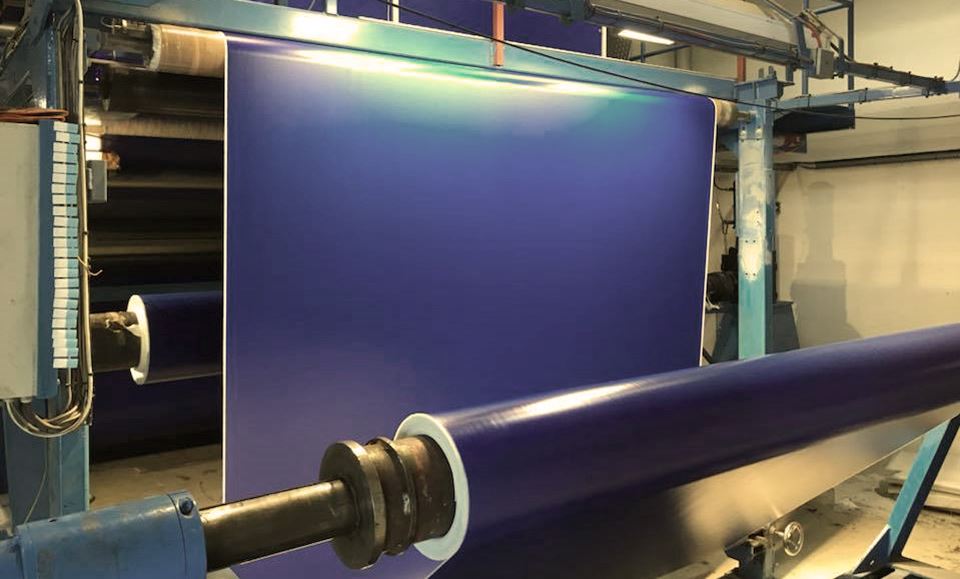

Production at Johan Castberg is set to start at the end of 2022 and the field is expected to have a lifespan of 30 years. Since the same production vessel will serve in this extreme climate for the entire time, there are especially high demands regarding the quality of materials used on the vessel. This obviously also applies to the fire barriers on the deck. To ensure this extremely high quality, products will be covered with Protan materials, thus making use of our expertise within membrane production as well as our experience within the oil and gas industry since the 1970s.

Protan PVC coated textiles covers are extremely durable and weather resistant and have many applications. This is why Protan is able to supply technical textiles to clients with various needs around the globe, from Arctic regions to the tropics. The equipment on the deck of the Johan Castberg vessel will therefore be well protected against both winter storms and fire with the Protan/Firesafe solution.

It is estimated that development of the Johan Castberg field will cost just under 50 billion kroner (43 billion British pounds), and it is expected to produce between 450 and 650 million barrels of oil in its lifetime. It is the most northerly oil field ever established on the Norwegian continental shelf, so when the vessel starts production at the end of 2022, it is reassuring to know that both people and installations will be securely protected with Protan and Firesafe’s unique products.